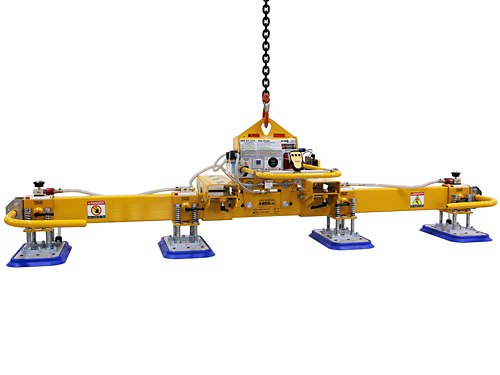

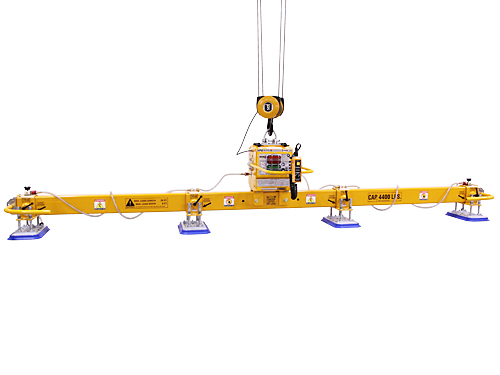

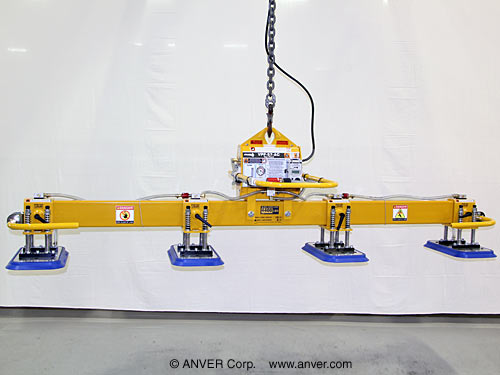

Four Pad Vacuum Lifter Lifting Frames

For Standard Four Pad Lifters – Capacity up to 4400 lb (1996 kg)

![]()

|

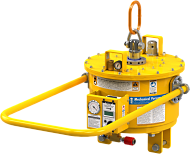

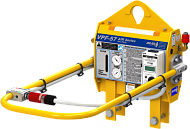

ANVER’S Standard Vacuum Lifters offer efficient material handling solutions by promoting functionality, safety, and ergonomic operations for a wide variety of applications and materials. Standard lifting frames are built to order from stock using modular components, so there are hundreds of possible combinations depending on the vacuum generator, beam, crossarms, and vacuum cups selected. Basic features on ANVER’s Standard Horizontal Vacuum Lifters include: vacuum leakage sensor and warning system; attach/release slide valve with safety lock; and locking hand knobs on the adjustable vacuum pad, slide assemblies, and crossarms (when applicable). ANVER Vacuum Lifters comply fully with and meet the standards of US ANSI ASME Standard B30.20 for below-the-hook lifting devices, as well as complying with OSHA and most European requirements. The L440M4-110, -150, -190, and -231 four-pad in-line lifting frames are ideal for handling carbon steel and stainless steel sheets and plates with a maximum capacity of 4400 lb (1996 kg). The type of vacuum lifter – Mechanical, Air, or Electric – paired with the number of pads used will depend on your application needs. Foam pads are not available for mechanical vacuum generators. Contact ANVER for more information, or fill out a Lifter Info/Quote Request Form and a Sales Engineer will respond to your request shortly. *Lifting frame shown with vacuum generator and/or optional accessories, not included. Unit weight does not include optional equipment. |

Standard Rubber Seal Lifting Frames Specifications

| Compatible Vacuum Generators | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| Mechanical | Air, Electric or Battery* | Electric | Battery* | Electric | ||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

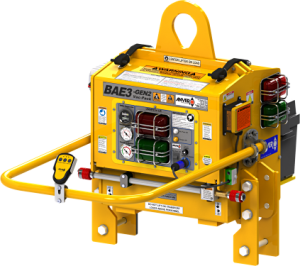

| M250M-Series | VPF-57-Series | VPE1-GEN3-Series | BAE1-GEN3-Series | VPE3-GEN3-Series | ||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

| Compatible Vacuum Generators |

|||||||||||||||||||||||||||||||||||||||||||||||||||

| Electric | Battery* | Electric | Battery* | ||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||

| VPE1-GEN3-Series | BAE1-GEN3-Series | VPE3-GEN3-Series | BAE3-GEN3-Series | ||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

*Battery powered vacuum generators are only recommended when handling non-porous loads.

| Various plate sizes can be handled by adjusting the vacuum pad positions on the beam | ||

Vacuum pads in maximum position to handle maximum plate size. |

Vacuum pads moved inwards to handle minimum plate size. |

Center vacuum pads (1/2 capacity) used for short, narrow plates. Outer pads provided with shut-off valves. |

| Installation | General Information | Safety |

| Support/Service | Options and Accessories | Request for Quote |

13600062 A