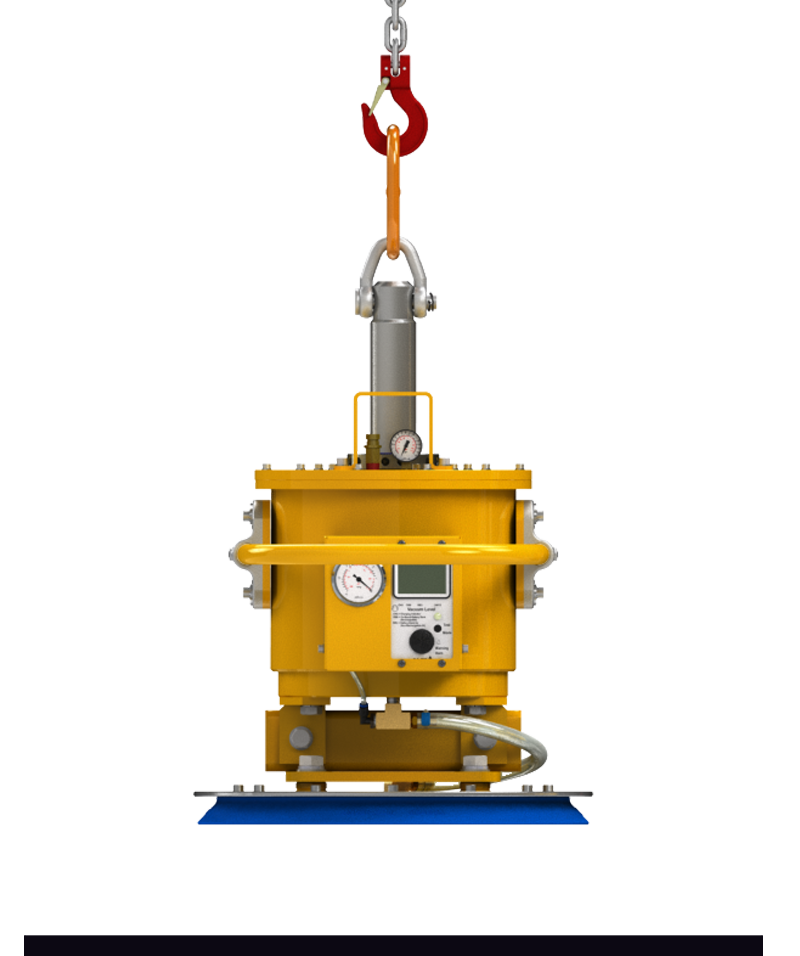

Mechanical Self-Powered, Self-Cycling Vacuum Lifters

No Power Service is Needed so Set-Up is Straightforward

Technical Description

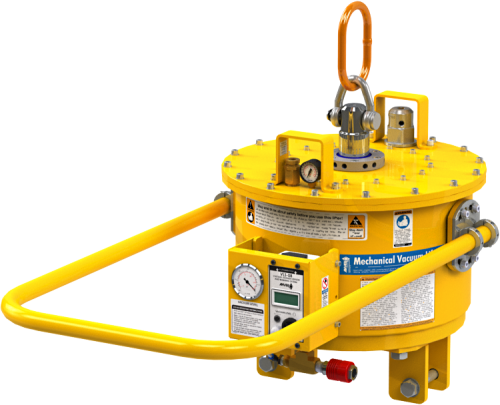

The vacuum generator consists of a free-moving piston within a closed cylinder. A rubber rolling diaphragm forms an airtight seal between the piston and cylinder. Since the integrity of this seal does not depend on metal-to-metal contact or a tight fit, it does not lose efficiency with use.

As the lifters are self-powered there is no installation required.

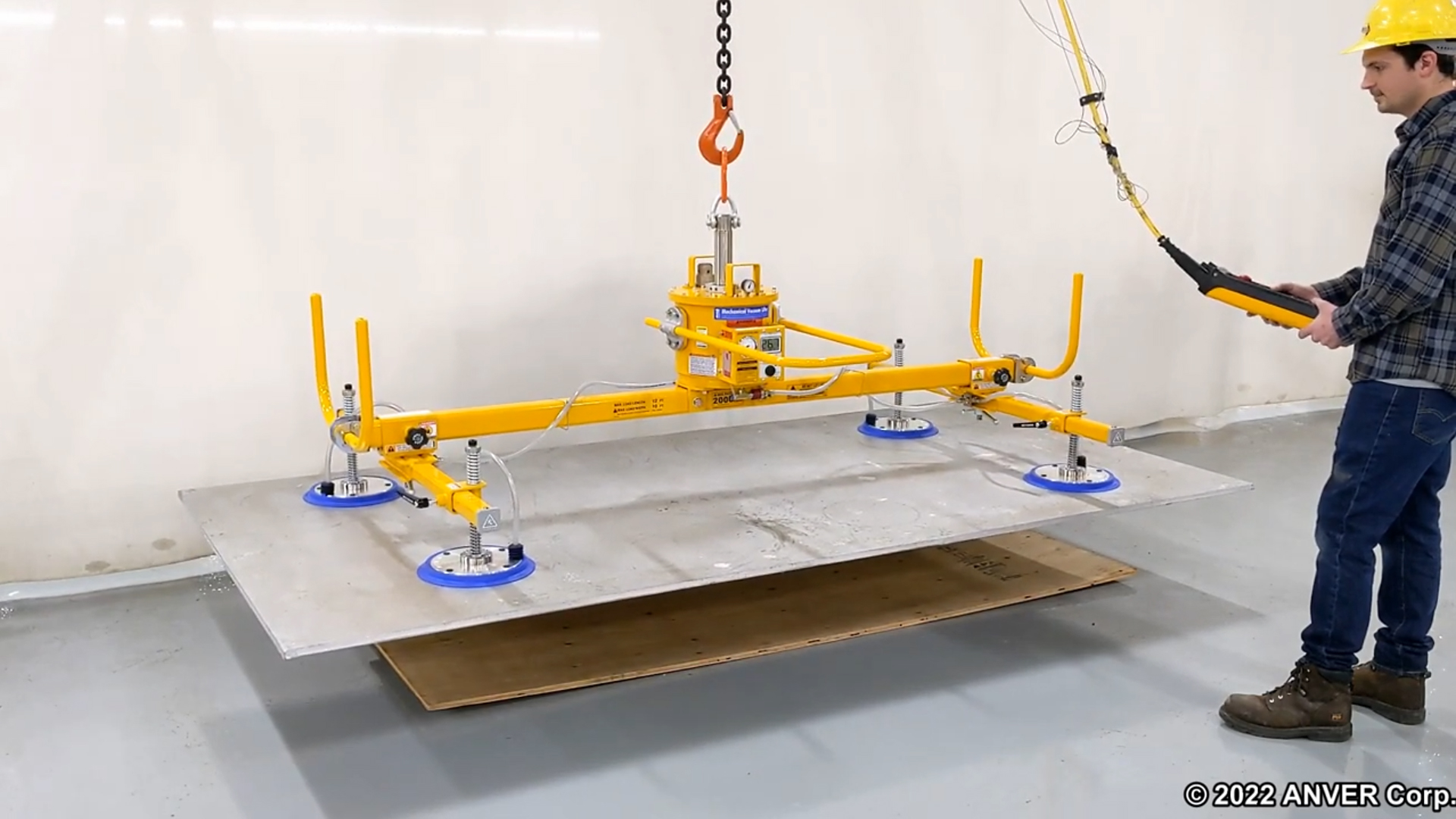

Mechanical Lifters require no electrical or compressed air service. Set-up consists of hanging the lifter on the crane hook. Its attach/release cycle is controlled by the hoist up/down movement. You can not release the load unless you set it down completely.

Go through the proper lifting procedures shown in your manual or the latest ANSI guidelines with your operators and you are done. The lifters come fully assembled and tested. It is that simple!

The vacuum attach-and-release cycle is controlled by an automatic self-cycling valve located in the bottom of the piston. When the unit is lowered onto the load and the suspension chain slackens the full weight of the lifter is on the load, and a cam automatically closes the piston valve. The hoisting action then pulls up the piston, creating a powerful vacuum inside the cylinder and underneath the vacuum pads.

When the load is completely set down, and the suspension chain is again slackened, the cam opens the piston valve, releasing the vacuum. The lifter then can be raised, ready for the next pickup. Attach and release are instantaneous. Since the valve sealing disc can only cycle when the chain is completely slack, it cannot shift positions while in use and will not accidentally release the load.

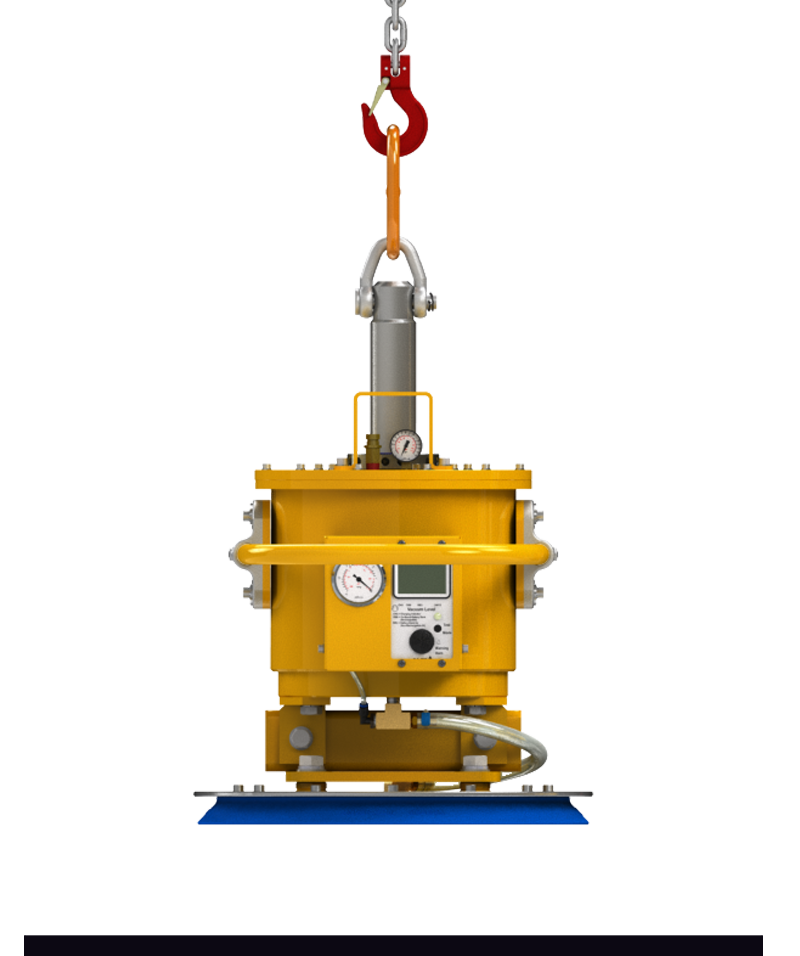

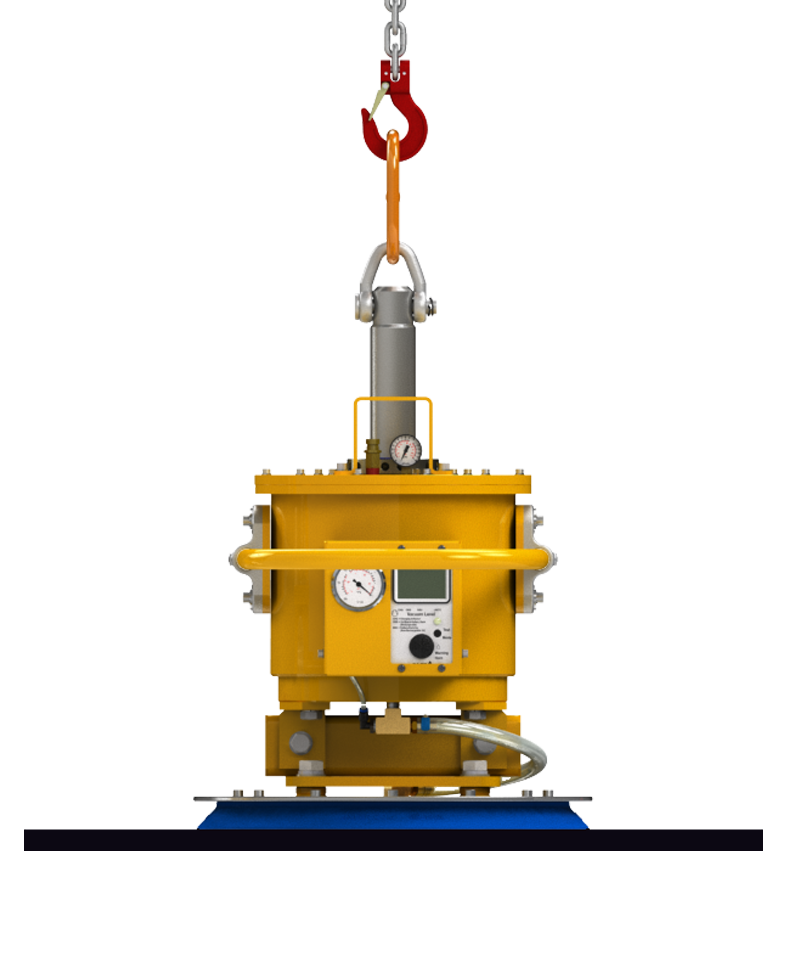

The lifter hangs from a crane hook and is lowered onto the load until the chain is slack.

The lifter hangs from a crane hook and is lowered onto the load until the chain is slack.

The lifter hangs from a crane hook and is lowered onto the load until the chain is slack.

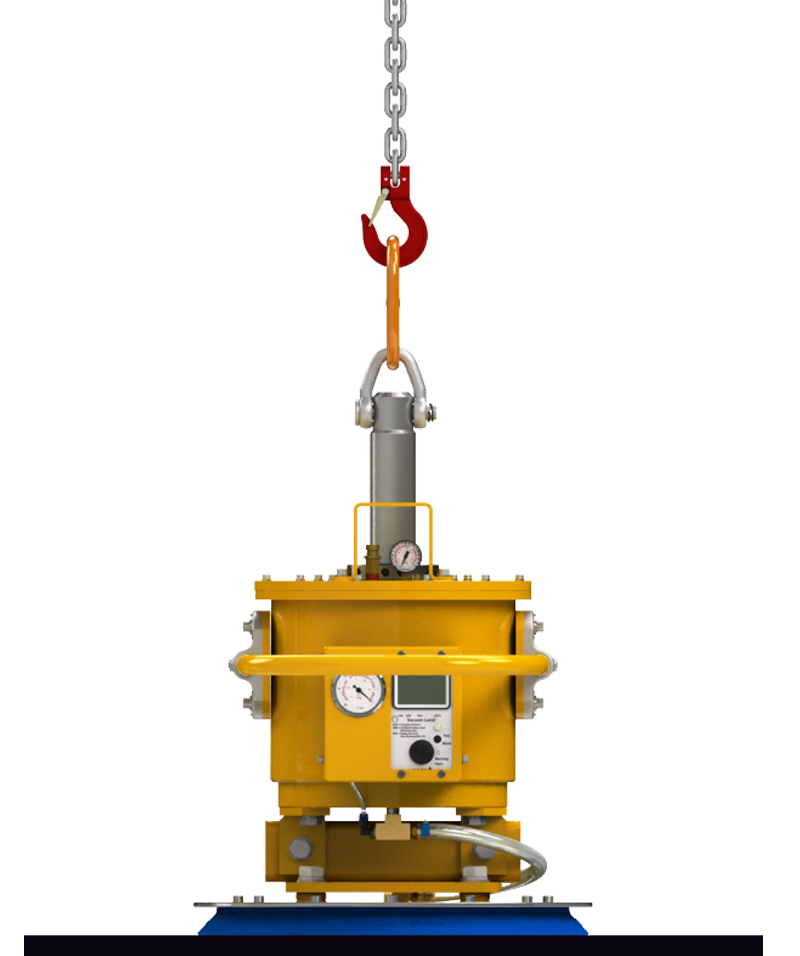

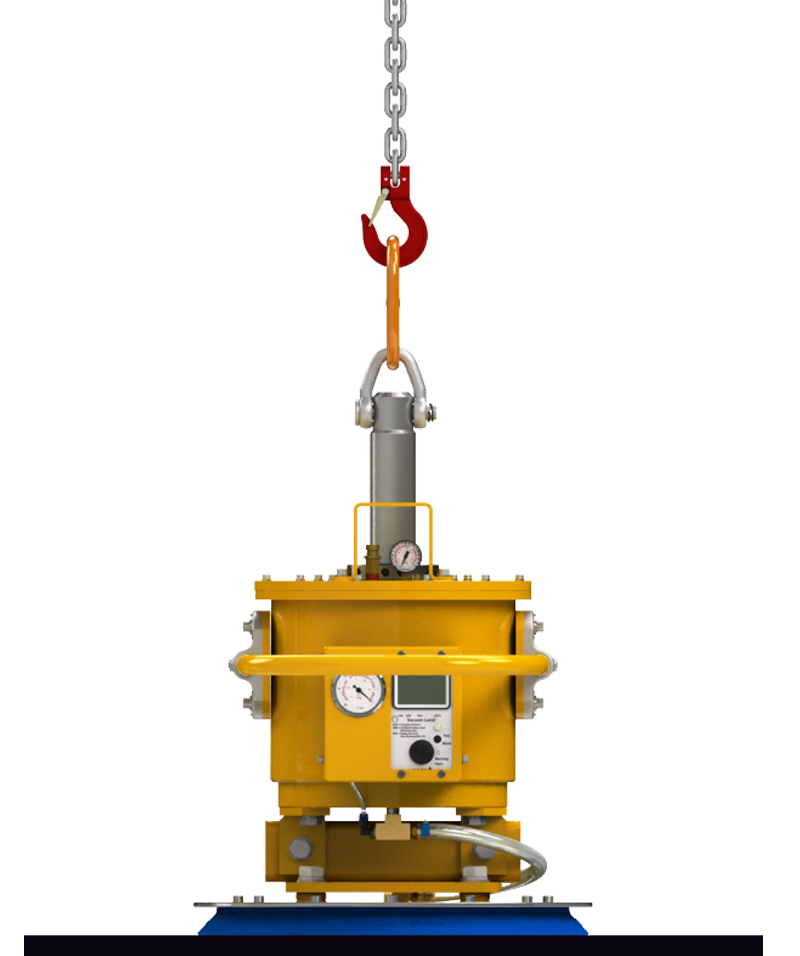

The lifter is pulled up by the hoist, creating a vacuum, and picks up the load.

The lifter is pulled up by the hoist, creating a vacuum, and picks up the load.

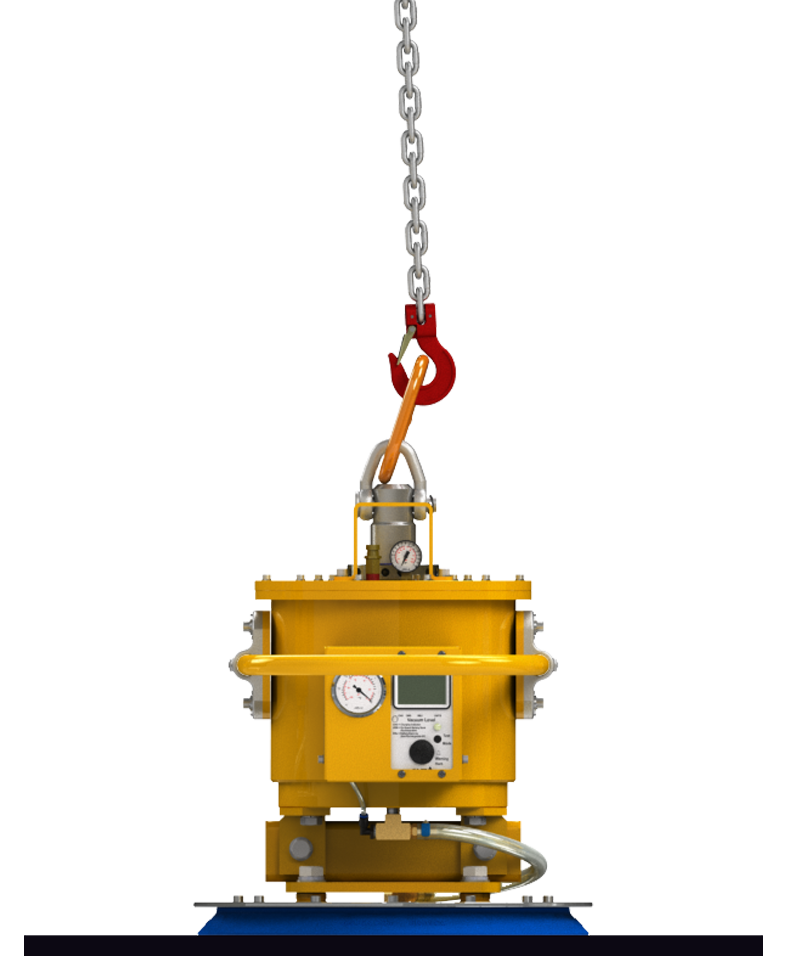

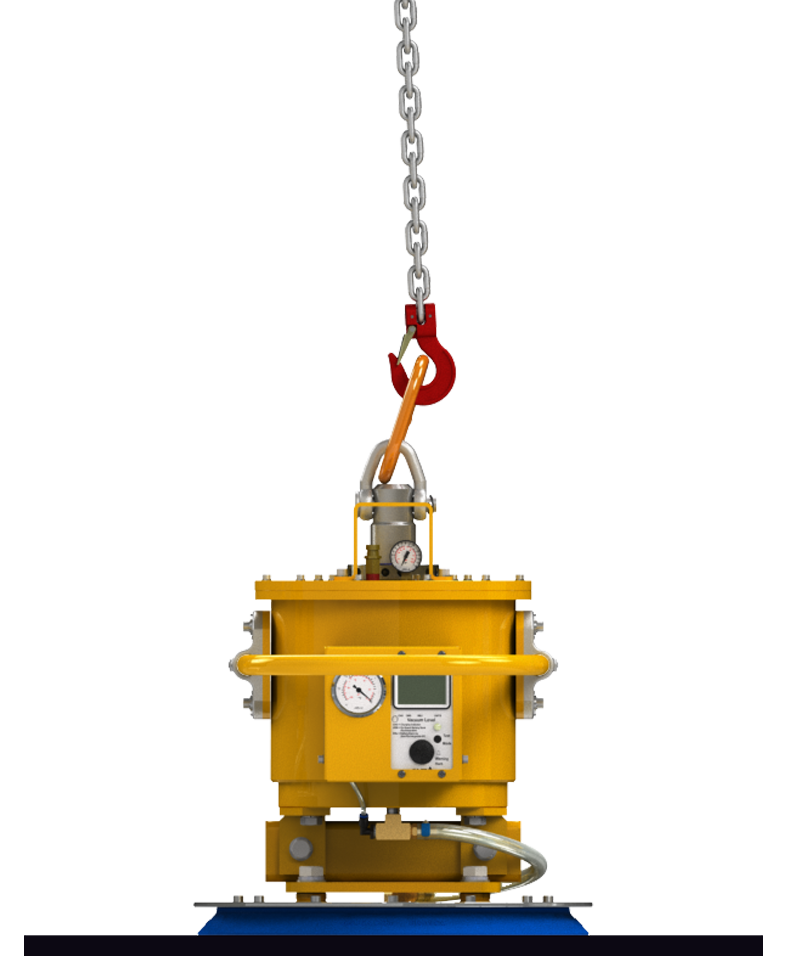

The lifter and load are set down until the chain is completely slack, which releases the vacuum.

The lifter and load are set down until the chain is completely slack, which releases the vacuum.

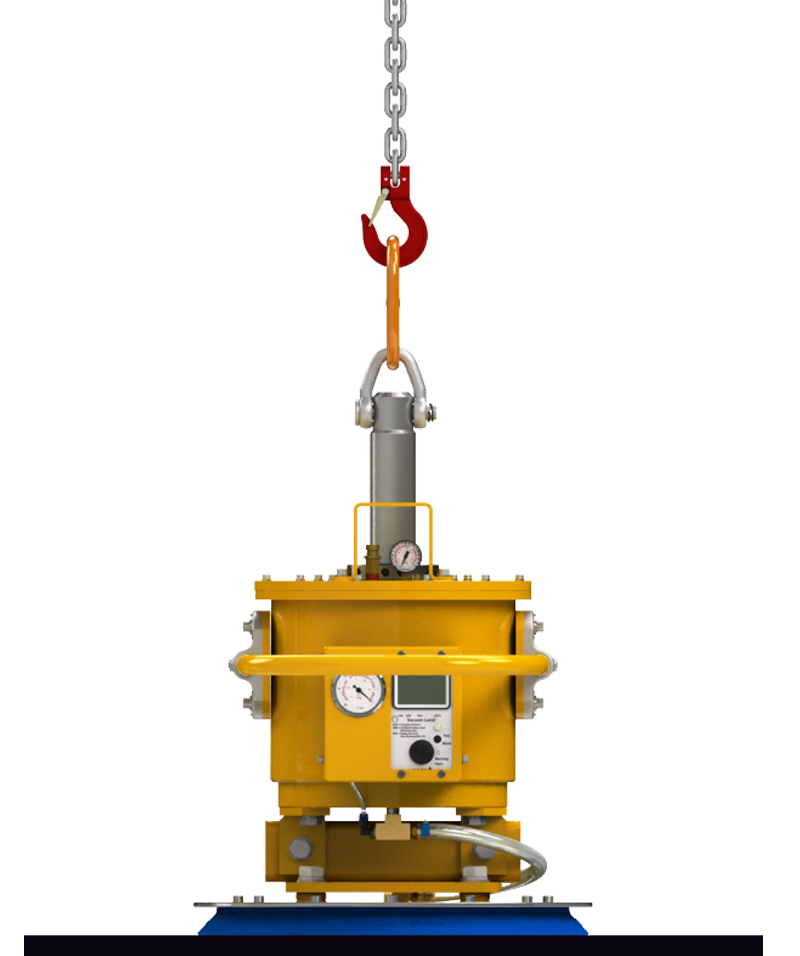

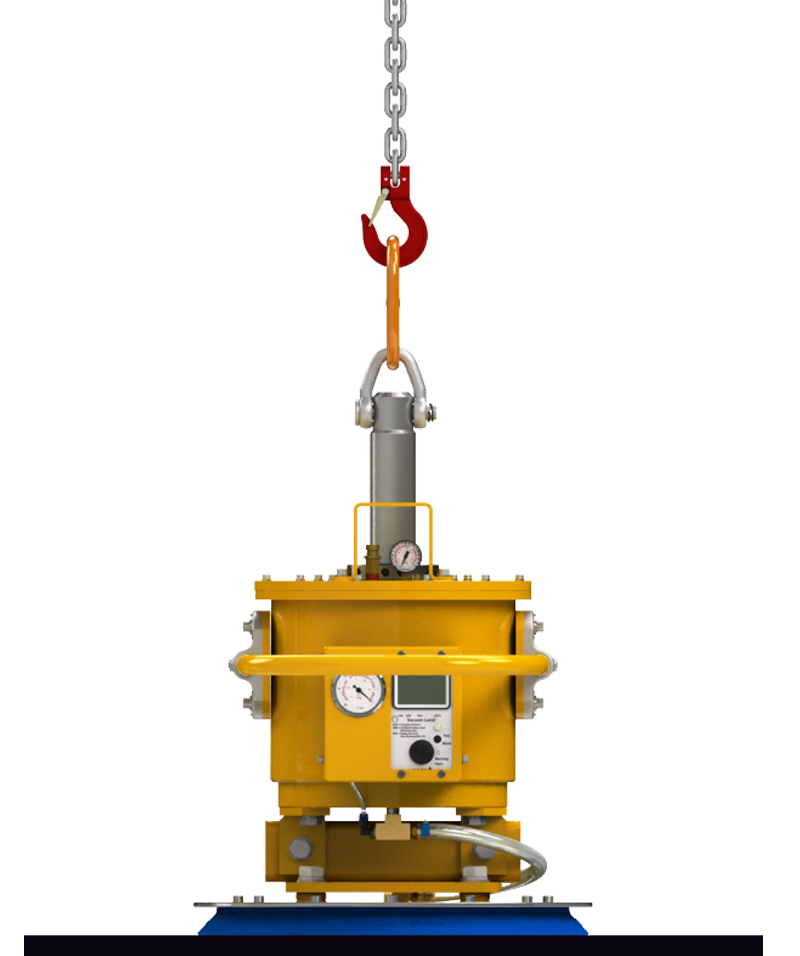

The lifter can now be raised without the load.

This completes the cycle and you’re ready to pick up the next load.

Make sure you have selected a Vacuum Lifter with adequate capacity to lift your heaviest load, and enough vacuum cups to support your longest, widest and thinnest load.

Click here to see how we calculate this.

Make sure your hoist and crane have adequate lifting capacity.

Remember, you need to deduct the vacuum lifter weight from the hoist and crane to get your overall capacity.

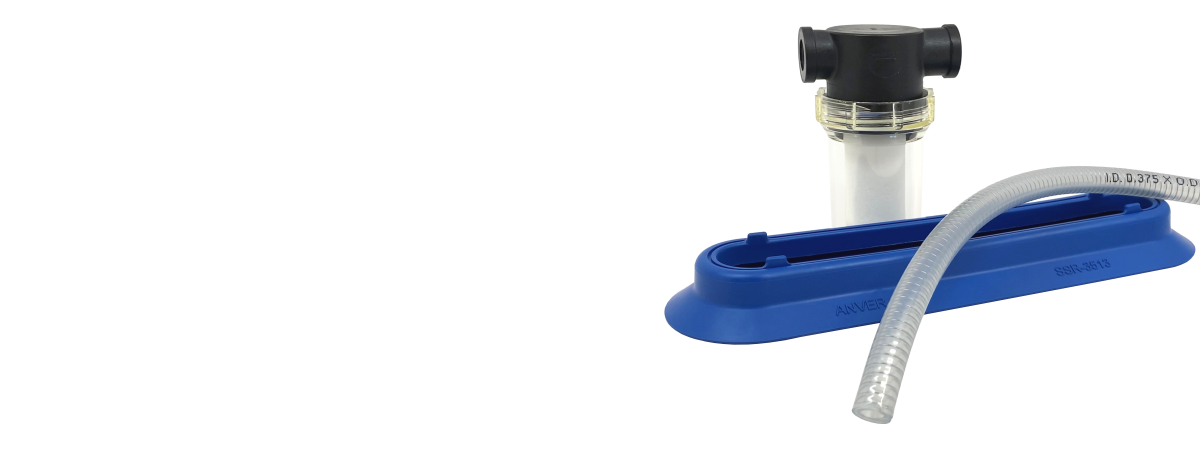

Spare and Replacement Parts

Have you ordered key spare parts such as vacuum cups or seals? While they do last, this will probably be the first item needing service.