VB Series Lift Systems – High Flow (Larger, Porous Loads)

Features and Specifications

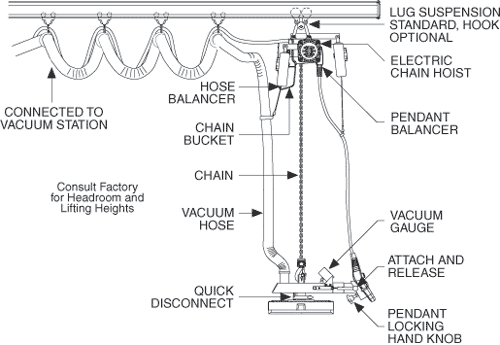

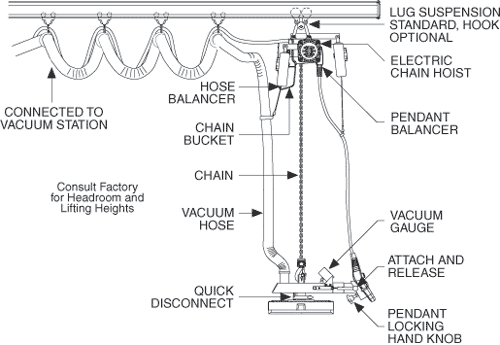

Air or Electric Powered Vacuum Pump with an Air Balancer or Electric Hoist for Lifting

|

|

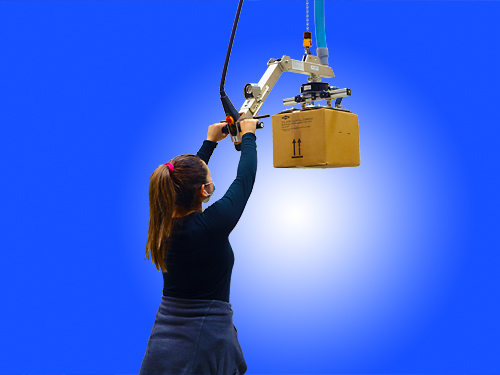

ANVER VB Vacuum Lifting Systems are fully integrated material handling systems designed for fast, safe, one person handling of bags, boxes and other porous-type loads. A large, ultra high vacuum, direct-drive vacuum pump provides the suction necessary for load attachment and holding; a rugged, electric chain hoist or an air balancer is used for load lifting. The VB Vacuum-Hoist Lifting System is a fully integrated lifting system for safe, controlled handling of heavy, porous loads with lifting capacities of up to 1100 lb (500 kg). |

|

-

Easy-to-use, ergonomically designed, fully integrated controls operate all system components. Up and down hoist movement is controlled by two push buttons for added safety.

-

Vacuum attachment of the load is continuous for maximum productivity. Electric hoists are suitable for one or two lifts per minute. (For higher production rates, an ANVER VT Vacuum Tube Lift System should be considered).

-

The vacuum system is used only to attach to and hold the load; the electric hoist or air balancer provides the lift. VB Vacuum-Hoist Lifting Systems are ideally suited for heavy or complex loads requiring sophisticated vacuum head attachments; for use with large crane systems; or for use under low-headroom mezzanines.

- VB Vacuum-Hoist Lifting Systems with compressed air powered hoists / air balancers with higher duty cycles, or for use in explosive environments, are also available. Contact ANVER for special applications.

|

|

Features:

- Precise Lifting The VB Vacuum-Hoist Lifting System chain hoist or air balancer provides secure up/down movement. The load can be set in position to hang exactly where set, with no vertical drift.

- Compact Headroom The VB system’s compact design requires little headroom. The standard lift length varies depending on which model is selected. Consult factory for headroom and lift length dimensions. Standard load capacities range from 275 to 1,100 lb (125 to 500 kg).

- Integrated Controls Easy-to-use, ergonomically designed, fully integrated controls mounted on the handle operate the hoist and vacuum release. Hoist up and down movement is controlled by two push buttons for safety. A gauge to indicate vacuum level is mounted on the control for monitoring by the operator. Extended length handles are also available.

- Dual or Variable Speed Chain Hoist The rugged electric chain hoist offers secure, precise movement and allows the operator to release or hold the load at an exact height. This feature is very useful for applications such as slowly pouring the contents of a bag into a hopper.

- Adjustable Vacuum Level The VB Vacuum-Hoist Lifting System’s vacuum level can be reduced temporarily as might be necessary for separating porous material such as individual sheets of particleboard from a stack.

- Independent Hoist Operation VB Vacuum-Hoist Lifting Systems combine the features of a vacuum lifter with those of a hoist and can be used for either purpose. The switchover is easy and takes only a few seconds. A built-in slip clutch stops the lift if the system is overloaded.

- Customized Systems VB Vacuum-Hoist Lifting Systems that use compressed air powered hoists / air balancers with higher duty cycles or for use in explosive environments are also available. Contact ANVER for special applications.

|

|

Click to Enlarge

|

|

Note: The shown bag emptying process works in most cases with ANVER’s VB Vacuum Lifting System (a unique capability) as the VB system is non-weight sensitive with a constant suction flow (unlike vacuum tube lifting systems).

|