|

Vacuum Holding Accessories Requires Less Than a Minute to Set Up • Simply and Quickly Attach the Clamp and Begin Welding • Clamp Quickly Releases for the Next Weld |

|

ANVER Compressed Air Powered Welding Hold-Down Clamps are supplied with a self contained hydraulic ram and pump that develops compressive force to help increase welding production and significantly reduce time and labor costs on a variety of welding operations. Welding operations include welding beams to plate or in the fabrication of tanks, cylinders and heavy structural sections. They also are an ideal means of raising a sagging plate to beam level. Welding of U-brackets and the use of wedges can be eliminated. There are no brackets to knock off or tack welds to grind when the welding operation is completed. The welding hold-down clamp is positioned over the sections to be welded. The vacuum attachment pads, powered by a compressed air venturi, are then activated, creating the holding force. The operator is able to accurately position the pieces to be welded while the hydraulic ram holds the pieces tight, helping to make a secure weld possible. A quick vacuum release valve permits movement of the unit to the next welding point quickly and easily. Features

|

|

|

Welding Vacuum Hold-Down Clamps

|

Specifications

|

Specifications

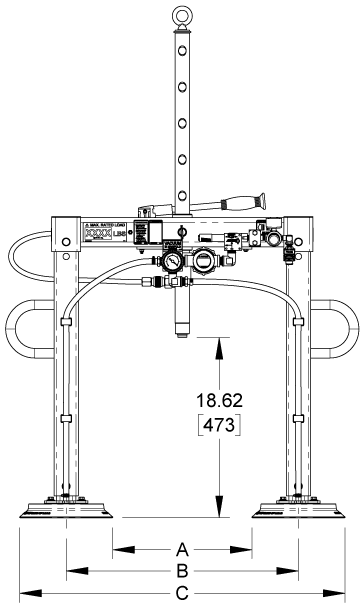

| Model No. |

Rated Load* [lb (kg)] |

Load Force at 1:1 [lb (kg)] |

A [in (mm)] |

B [in (mm)] |

C [in (mm)] |

Unit Wt. [lb (kg)] |

Vacuum Cup / Pad No. |

Pad Size [in (mm)] |

|

| WCAL50 | 500 (227) |

1000 (454) |

14 (356) |

24 (610) |

34 (864) |

55 (25) |

VP96-NBR | 10.0 (254) |

|

| WCAL100 | 1000 (454) |

2000 (908) |

11 (279) |

24 (610) |

36 (914) |

75 (34) |

VC119-4 | 12.5 (318) |

|

| WCAL100-OC | 1000 (454) |

2000 (908) |

17.6 (447) |

24 (610) |

30.63 (778) |

78 (36) |

VP720-NBR | 19.50 x 6.63 (495 x 168) |

|

| WCAL150 | 1500 (680) |

3000 (1360) |

15 (381) |

30 (762) |

45 (1143) |

95 (43) |

VP145S | 14.5 (368) |

|

| WCAL250 | 2500 (1135) |

5000 (2270) |

11 (279) |

30 (762) |

49 (1245) |

120 (55) |

VP185S | 18.5 (470) |

|

| WCAL400 | 4000 (1800) |

8000 (3600) |

14 (356) |

36 (914) |

58 (1473) |

140 (64) |

VP215S | 22.0 (559) |

* Rated load at 24 in. Hg, with a 2:1 safety factor on vacuum holding.