Compressed Air Powered Vacuum Generators

Self-Contained Air Powered Vacuum Stations

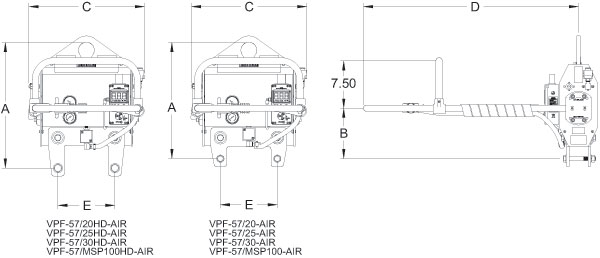

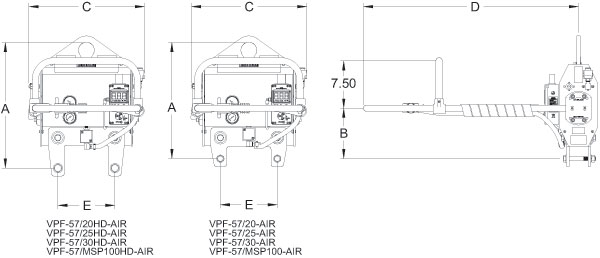

VPF-57-AIR Series

|

ANVER’s latest models of vacuum generators feature high capacity pumps, valves, filters and gauges for trouble-free operation in the most demanding production environments. Designed for use with a wide assortment of vacuum lifter assemblies and interchangeable pad attachments, these high quality Vac-Packs are ruggedly built, yet affordably priced for unmatched value. The VPF-57-AIR Series features a sturdy welded frame construction for heavy weight load lifting capability.

|

|

Features:

- Air Powered Vacuum Generator

No electric power required, operates using dry, clean compressed air for vacuum generation. The vacuum generator is a single stage unit with no moving parts or rubber gaskets to maintain or replace.

- Takes Standard Dry, Clean Shop Air

Input pressure to be regulated to 90 psi (72.5 psi on VPF-57/30-AIR). Provided with 3/8” NPT

- Energy Air Saver Vacuum Generator:

The vacuum controlled valve shuts off the flow of compressed air to the pump when the pre-set level is reached, and consequently the consumption of compressed air is minimized. (Not available on VPF-57/-30-AIR)

- Vacuum Leakage Sensor and Warning System

The VLS is a battery powered unit consisting of solid state circuitry with microprocessor, pressure sensor, LCD digital display in inches of Hg, and audible and visual warning signs (horn and red light). System is plumbed to the Vac-Pack and monitors vacuum level triggering the alarm in the event of a leakage in vacuum level (10% leakage for VLS / 20% leakage for VLS-20).

- Front Mounted Gauges

Includes both an input air pressure and vacuum indicator gauges, front mounted for continuous monitoring by the operator. Also included is a filter view port to monitor filter for cleaning.

- Ergonomic Adjustable Front Handlebar

Easy to grasp, large loop handlebar enables the operator to easily and safely maneuver the attached load without touching the load itself. Handlebar can be adjusted for smaller loads.

- Slide Control Valve with Push-Button Safety Lock

The slide valve assembly allows vacuum attach and release and is mounted to the front handlebar for convenient access by the operator. The push-button safety lock is to keep the slide valve in the attach position while lifting a load to prevent accidental load release.

- Vacuum Check Valve and Reservoir

A check valve and a vacuum reservoir help to maintain vacuum if the supply of compressed air is interrupted, for safe handling of non-porous loads.

|

|

Maintenance:

- Air Filter

High capacity air filter provides protection against pump damage. It is mounted behind the front cover which has a view port for routine inspection.

|

|

General:

- Frame Construction

The VPF-57-AIR Series has a fully welded frame with a vacuum reservoir and a lifting bail and beam mounting hardware.

• Standard for 3”x3” beam [9” hardware centers] with a structural lifting capacity rating up to 2,200 lbs (998 kg).

• Heavy Duty for 3”x6” beam [9” hardware centers] with a structural lifting capacity rating up to 4,400 lbs (1,996 kg).

- Versatility

For larger load lifting capability or alternate power requirements, ANVER offers electric powered and self-powered mechanical vacuum generators, all with standard mounting designs for interchangeability.

|

Specifications:

|

| Request For Quote | | | |

| Generator Model Number | VPF-57/20-AIR | VPF-57/25-AIR | VPF-57/30-AIR |

| Rated Load Capacity (3x3 Beams) [lbs (kg.)] | 2200 (998) | 2200 (998) | 2200 (998) |

| Rated Load Capacity (3x6 Beams) [lbs (kg.)] | 4400 (1996) | 4400 (1996) | 4400 (1996) |

| Unit Weight (3x3 Beams) [lbs (kg.)] | 56 (25) | 56 (25) | 56 (25) |

| Unit Weight (3x6 Beams) [lbs (kg.)] | 60 (27) | 60 (27) | 60 (27) |

| A Max. Headroom (3x3 Beams) [in. (mm)] | 18 (457) | 18 (457) | 18 (457) |

| A Max. Headroom (3x6 Beams) [in. (mm)] | 20 (508) | 20 (508) | 20 (508) |

| B Handlebar Height (3x3 Beams) [in. (mm)] | 8 (203) | 8 (203) | 8 (203) |

| B Handlebar Height (3x6 Beams) [in. (mm)] | 10 (254) | 10 (254) | 10 (254) |

| C Handlebar Width [in. (mm)] | 18 (457) | 18 (457) | 18 (457) |

| D Handlebar Length [in. (mm)] | 34 (864) | 34 (864) | 34 (864) |

| E Hardware Centers [in. (mm)] | 9 (229) | 9 (229) | 9 (229) |

| **Vacuum Flow [SCFM] | 4.5 | 7.06 | 9.5 |

| Air Consumption [SCFM] | 6.1 | 9.2 | 14 |

| Application | Smooth,

Non-Porous | Rough,

Semi-Porous | Rough,

Semi-Porous |

| Energy Saver / Quiet Automatic Shut-Off | YES | YES | NO |

|

* Note: Optimum pressure is 90 psi. (72.5 psi on VPF-57/30-AIR) Air supply flow (CFM) may adversely affect required pressure (psi) to achieve optimum vacuum level. Vacuum level is 24″ Hg at sea level. Due to Energy Saver Technology, air consumption is “0” on a non-porous material once the vacuum level is reached at peak value. Energy Saver not included with VPF-57/30-AIR.

**Note: High Flow version available, please contact factory for more information.

13600009

![]()