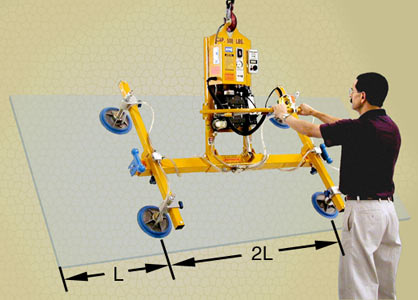

Weight and Overhang Guide

Glass Lifting

To ensure proper lifter selection for glass loads, consult an ANVER Applications Engineer with your load specifications. or click here to request a quote.

|

|

ANVER recommends the use of secondary safety slings (glass slings) when handling vertical glass panels with vacuum lifters.

If an insulated glass panel or outside frame separates, or a crack goes across a vacuum cup(s), or slippage occurs due to a wet surface only a separate sling can stop from losing the load. Even a full dual vacuum lifter with two systems on one frame cannot guard against these issues.

In the rare event of loss of vacuum, secondary safety slings are the best option to secure the load to be lowered to the ground.

Vacuum cups must be directly on glass without any plastic film. Film can separate from the glass and plug the orifice on the pad which would give a false reading and no vacuum under the pad.