|

Picker |

Resting |

Maximum |

Overall d Dia. in. (mm) |

d1 |

Overall |

Rubber |

|

|

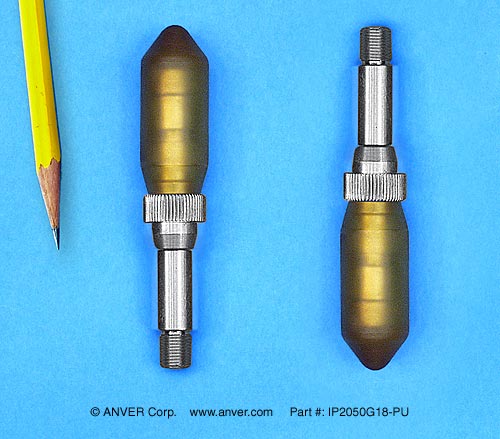

IP2050G18-PU |

0.79 (20) |

1.10 (28) |

0.73 (18.5) |

G 1/8″ | 3.98 (101) |

1.97 (50) |

|

Picker |

Resting |

Maximum |

Overall d Dia. in. (mm) |

d1 |

Overall |

Rubber |

|

|

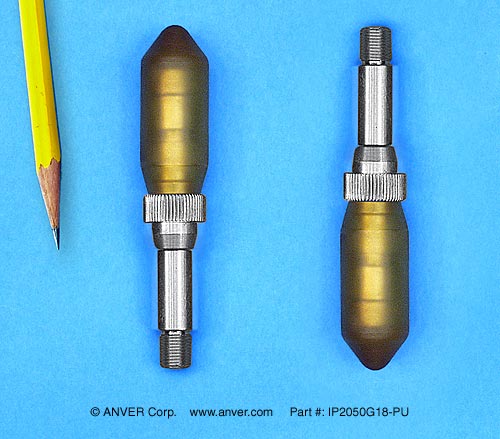

IP2050G18-PU |

0.79 (20) |

1.10 (28) |

0.73 (18.5) |

G 1/8″ | 3.98 (101) |

1.97 (50) |

|

Furthering its commitment to offer safe and efficient vacuum lifting solutions, ANVER Corporation introduces the new VPE1-GEN2 Series Vacuum Lifter Generator. Designed especially to handle non-porous to semi-porous loads, these rugged generators can withstand heavy production use and they are compatible with an extensive selection of ANVER vacuum pad attachments and lifter assemblies. The newly designed VPE1-GEN2 Series Vac-Pack is full of safety features, giving operators peace of mind when lifting loads. To remove the risk of accidental release by an operator, the Vac-Pack has a load sensitive lifting bail with safety lock-out that insures the pendant controls are active only when the lifter and load are lowered completely (available on most horizontal models), and a separate attach and release safety lock-out mechanism on the control pendant itself. A solid-state Vacuum Control Module houses all the required vacuum generator controls in one sturdy unit, including safety lights and the VLS-03E audible vacuum leakage warning system. The VLS-03E sounds an alarm if a slow vacuum leak is present and the vacuum level drops to a pre-determined set point. In the event of a power failure, the VPE1-GEN2 Series has an internal check valve to stop vacuum loss, in addition to a large vacuum reservoir to assist in maintaining a safe vacuum level for non-porous loads. Other standard features include an ergonomic control handlebar that is easy to grasp and allows operators to easily and safely maneuver an attached load without touching the load itself. The large loop handlebar can be adjusted for smaller size loads. All gauges, indicator lights, and power switches are mounted on the front of the control panel for easy visibility and accessibility. The control pendant clip mounts to the front handle on a 10 ft. coiled cord and provides rapid attach and release functions at the operator’s fingertips. Units are available with heavy duty frames for mounting remotely. The VPE1-GEN2 Series has a rated load capacity up to 4,600 lbs (2,087kg) depending on the model and pad attachment. Optional generator configurations and set-ups are available. Contact ANVER for further information and application requirements. |

Click Here for more Product Information

Bottle Gripper Head Solutions from ANVER Corp. Address Demanding Manufacturing Challenges

Pneumatic-Powered Bottling Pick-Up Grab Heads for Use with Major Lines of New or Replacement Bottling Machinery

Hudson, MA/February 11, 2016/ — ANVER Corporation, a leader in vacuum handling technology, announces its line of pneumatic-powered bottling pick-up heads for robotic and automation equipment, utilizing inflatable bladders and pneumatically actuated mechanical grippers to gently grasp bottles from the inside or the outside.

These end-of-arm tool (EOAT) pick-up heads are designed for high-speed, controlled pick-and-place assembly. They feature pliable, non-marring elastomeric bladders that inflate using minimal pressure to pick up bottles and containers from either inside the open mouth or outside the neck. The internal air bladder, or piston actuator, used to grip the neck of a bottle or container is achieved by using a three-way valve and less than 30 psi of compressed air, which will not crush or break material. A simple air control valve releases the grip with agile precision, completing the instant attach-and-release processing cycle.

Offered in a wide range of FDA-approved materials, styles, and sizes, ANVER’s pick-up heads work well with filled or empty glass or plastic bottles. They are an excellent solution to lift, move, pack, and unpack bottles or similar objects of varying sizes and shapes, and they are perfect for use in the food, soft drink, beer, wine, spirits, pharmaceutical, and chemical industries.

ANVER’s end-effector pick-up heads are compatible with all major lines of pick-and-place bottling and packaging systems. Constructed of high-impact plastic, aluminum, elastomer, and stainless parts, these bottle grabs are light-weight yet durable. Replaceable bladders extend the life of the system.

Based on the application, ANVER’s dedicated sales engineers can help customers find the most suitable design for optimized efficiency and value. ANVER also offers a complete line of labeling and other components for a comprehensive bottle handling solution.

About ANVER Corp

ANVER, founded in 1968, is a North American leader in vacuum handling technology. ANVER is a full-service manufacturer offering a complete range of vacuum handling products from miniature vacuum suction cups and vacuum pumps to complete Mill-Duty Vacuum Lifting Systems.

For more information, please contact:

ANVER Corporation

36 Parmenter Rd.

Hudson, MA 01749

J.J. Osmecki, Group Manager

Phone: +1-978-568-0221

E-mail: info@anver.com

Website: www.anver.com

|

Please fill out the form below to the best of your ability. If you do not know the information for a section, or you feel it is not relevant please leave it blank. Not all fields on this form are relevant to every application.

|