Vacuum Pumps and Vacuum Generators

Air Mover Style Vacuum Pumps

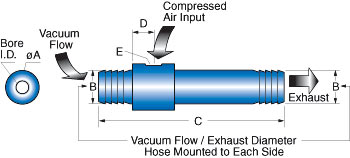

FT Series Adjustable Flow Tubes and Transfer Tubes

![]()

-

Product Photo

(Click to Enlarge)Model

NumberBore ID

in.

(mm)Air

Usage*

SCFM

(l/min.)Output*

SCFM

(l/min)Max. Vac.

in. Hg

(mm Hg)Amp-

lification

RatioA

in.

(mm)B

Barb

in.

(mm)C

Approx.

in.

(mm)D

in.

(mm)E

Inlet

PortF

Barb

in.

(mm)G

in.

(mm)

(CDF200H

KVPCOF200H)0.25

(6.3)3

(85)18

(340)5

(127)6:1

1.32

(33.4)0.53

(13.5)3.75

(95.3)2.10

(53.5)G 1/8″ 1.00

(25.4)0.94

(24.0)

FT050 **

(CDF500H

KVPCOF500H)0.50

(12.7)9

(255)75

(2124)3

(76)8:1

1.90

(49.0)1.00

(25.4)4.50

(114.5)2.13

(54.0)G 1/4″ 1.50

(38.1)0.94

(24.0)

(CDF750H

KVPCOF750H)0.75

(19.1)9

(255)110

(3115)1.5

(38)12:1

2.38

(60.4)1.25

(31.8)4.97

(126.0)2.63

(66.7)G 1/4″ 2.00

(52.0)0.94

(24.0)

(CDF1000H

KVPCOF1000H)1.00

(25.4)9

(255)145

(4106)1

(25)16:1 2.38

(60.4)1.50

(38.1)4.97

(126.0)2.53

(64.1)G 1/4″ 2.00

(52.0)0.94

(24.0) -

Product Photo

(Click to Enlarge)Model

Number(B)

Optional

Hose to Fit Exhaust Barb(E)

Optional

G to NPT

Inlet Port Adapter(F)

Optional

Hose to Fit Incoming BarbOptional Clamp

Mount

(CDF200H

KVPCOF200H)

FT050 **

(CDF500H

CD500H

KVPCOF500H)

(CDF750H

KVPCOF750H)

(CDF1000H

KVPCOF1000H)

* Air usage and output are based on an input pressure of 80 PSIG.

** Note: Optional CLAMP51P requires tape wrap to fit tightly on FT050.

13600162 A

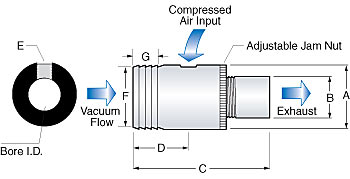

Air Movers: TT Series Material Transfer Tubes

![]()

|

The TT Series Transfer Tubes offer a simple, effective, and low cost solution to perform an inline transfer of small or complex shaped objects, bulk material, and powders. Highly efficient and compact, the TT Series creates an instantaneous and adjustable vacuum flow that is powered by compressed air. The straight-through, smooth bore design allows material to pass directly through the pump at high speeds without clogging. These transfer tubes are made of anodized aluminum and are available in 4 standard models with inside diameters from 3/8″ (9.5mm) to 1″ (25.4mm). |

|

|

Applications

|

|

|

|

||

-

Product Photo

(Click to Enlarge)Model

NumberBore ID

in.

(mm)Air

Usage*

SCFM (l/min)Output* SCFM

(l/min)Max.

Vacuum

in. Hg

(mm Hg)Velocity ft/sec

(m/sec)A

in.

(mm)B

Barb

in.

(mm)C

in.

(mm)D

in.

(mm)E

Inlet

Port

TT03 (DF3-3 D3-3

KVPDF3-3)0.375

(9.5)10

(283)15

(425)6

(152)395

(120)1.25

(31.8)0.75

(19.1)3.75

(95.3)0.50

(12.7)G 1/8″

TT05 (DF5-6 D5-6

KVPDF5-6)0.500

(12.7)24

(680)30

(850)6

(152)360

(110)1.50

(38.1)1.00

(25.4)5.75

(146.1)0.63

(15.9)G 1/4″

TT07 (DF7-6 D7-6

KVPDF7-6)0.750

(19.1)48

(1359)60

(1699)8

(203)325

(99)2.00

(50.8)1.25

(31.8)8.00

(203.2)1.00

(25.4)G 1/4″

TT10 (DF10-3 D10-3

KVPDF10-3)1.00

(25.4)48

(1359)95

(2690)6

(152)290

(88)2.25

(57.2)1.50

(38.1)8.00

(203.21.00

(25.4)G 1/4″

-

Product Photo

(Click to Enlarge)Model

NumberOptional

Hose to Fit Both BarbsOptional

G to NPT

Inlet Port AdapterOptional Clamp

Mount

TT03 (DF3-3 D3-3

KVPDF3-3)

TT05 (DF5-6 D5-6

KVPDF5-6)

TT07 (DF7-6 D7-6

KVPDF7-6)

TT10 (DF10-3 D10-3

KVPDF10-3)

* Air usage and Output are based on an input pressure of 80 PSIG.

13600163 A

The “G” thread is also known as BSPP, commonly used world-wide for vacuum applications.